Radically Responsive. Relentlessly Reliable.

MORE THAN A CRUSHER PART SUPPLIER,

WE'RE YOUR ENGINEERING PARTNER

Service & Support

Mantle & Bowl Liners

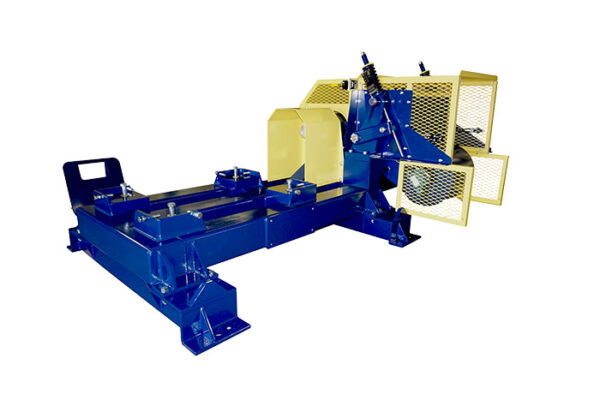

Crusher Parts

Optimum Crush isn’t just a name – it’s how we do business.

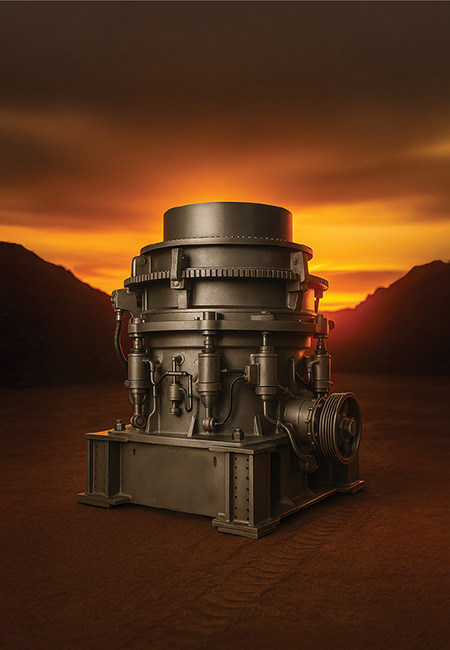

Simply put, we maximize production up-time and lower operating costs at mines and quarries all over the world. We do this by creating custom-engineered mining and quarry supplies such as mantles, bowl liners and other custom parts as rock crusher solutions to reduce wear and optimize your machines. In addition to our best in-class parts and services, we also have seasoned engineers that not only work directly with you on-site, but also offer training and 24/7 technical support to ensure you are always up and running.

Optimum Crush is a crusher parts supplier and provides support for the FLSmidth® Raptor® XL500, XL600, XL900, XL1100, XL1300, and XL2000 machines as well, as Metso® and Telsmith® products. Optimum Crush uses engineering principals combined with decades of crusher experience to develop our own designs and products that fit into these machines. In many cases the designs we offer provide improvements in reliability, durability, or life over the OEM products.

From top to bottom, we’ve got you covered.

FLSmidth® and Raptor® are trademarks of FLSmidth A/S. Optimum Crush is not an authorized repair facility nor is it affiliated with FLSmidth. These marks are used for identification purposes only. All parts are manufactured by, for, and warranted by Optimum Crush and are not manufactured by, purchased from, or warranted by the original equipment manufacturer, unless otherwise noted.

CRUSHER PARTS

Are you looking for quality parts to increase the efficiency of your mine? We work with mines around the world supplying them with custom engineered crusher parts. While most OEM’s operate at a warranty rate of 3% of total sales, our warranty rate is at 0.17% of total sales. That speaks directly to our commitment to quality and custom fit.

Our products and services are sold across the world to countries such as the USA, Canada, Mexico, Chile, Peru, Australia, Philippines, Papua New Guinea, Mauritania, and several more.

OUR COMPANY

Crusher Engineers

Our team knows your machines inside and out. We are experts and aren't afraid to get our hands dirty.

24/7 Support

We are here for you when you need us. Our team is available 24 hours a day, 7 days a week.

Community

Part of our mission is to support the communities around the mines we work in.

Speed of Delivery

We keep stock for common parts and products and are ready to ship the same day.

Optimum Crush Blog

TESTIMONIALS

COMMUNITY OPTIMIZATION

At Optimum Crush, we care deeply about the communities that support our customers around the world. We’re grateful for every opportunity we’ve been given, and we believe in giving back to the people and places that make our work possible.

We know that strong mining operations depend on strong communities. That’s why we’re passionate about helping build those connections by supporting local organizations that make a real difference.

Whether it’s sponsoring scholarships, youth sports teams, 4H clubs, local churches, or other nonprofits, we’re proud to stand beside the people who make their towns thrive.

At the heart of it all, our goal is simple — to create long-lasting relationships that benefit everyone. Because we don’t just want to work in your community — we want to be part of it.